Hydraulic & Pneumatic Cylinders

Cylinders are essential components of any manufacturing plant or process. Given their importance, it is imperative that the cylinders used are of good quality and are easily available.

Since its inception in 2005, Spectrum Hydraulics has been committed to just that: providing our customers with cylinders of very good quality at reasonable prices. Over the years, we have been able to fulfill our commitment with the help of a dedicated team and a fully equipped manufacturing plant. Our plant is equipped to manufacturecylinders that can withstand pressures of upto 400 bar. The maximum size that can be produced is a cylinder with a Bore of 1000mm and a Stroke of 8 meters.

Types of Cylinders Manufactured:

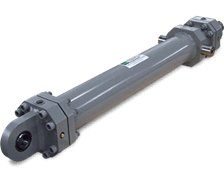

Mill – Duty Cylinders:

In this type of construction, the end cap and gland are bolted to the cylinder tube flanges.

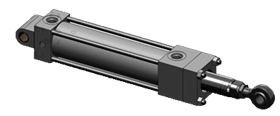

Tie – Rod Cylinders:

In this type of construction, high strength threaded steel rods are used to hold the two end caps to the cylinder barrel. Tie rod style cylinders can be completely disassembled for service and repair.

Welded Cylinders:

In this type of construction, the barrel is welded directly to the end caps. The ports are welded to the barrel. The front rod gland is usually threaded into or bolted to the cylinder barrel.

In addition to the aforementioned standard types of cylinders, we also specialize in creating cylinders that are tailor made for our customer’s requirements. We are always at hand and are ready to visit customers, develop cylinder drawings based on their needs and offer replacements for non- standard hydraulic cylinders.

Cylinder Design:

Design parameters are an important factor to take into consideration when making a cylinder. Ensuring that these parameters are within the acceptable range is essential for improved cylinder life.

At SHT, some of the many parameters that are taken into account are as follows:

- Tensile Strength of Piston Rod, Cylinder flanges, fasteners and Rod end thread

- Shear Strength of Piston Rod, Cylinder flanges, fasteners and Rod end thread

- Material Strength of Clevis

- Hoop Stress

- Buckling of Piston Rod

With the ultimate aim of complete customer satisfaction, our design team works meticulously with the skilled technicians at our plant to ensure that our cylinders are perfectly suited to the conditions under which they mustwork.